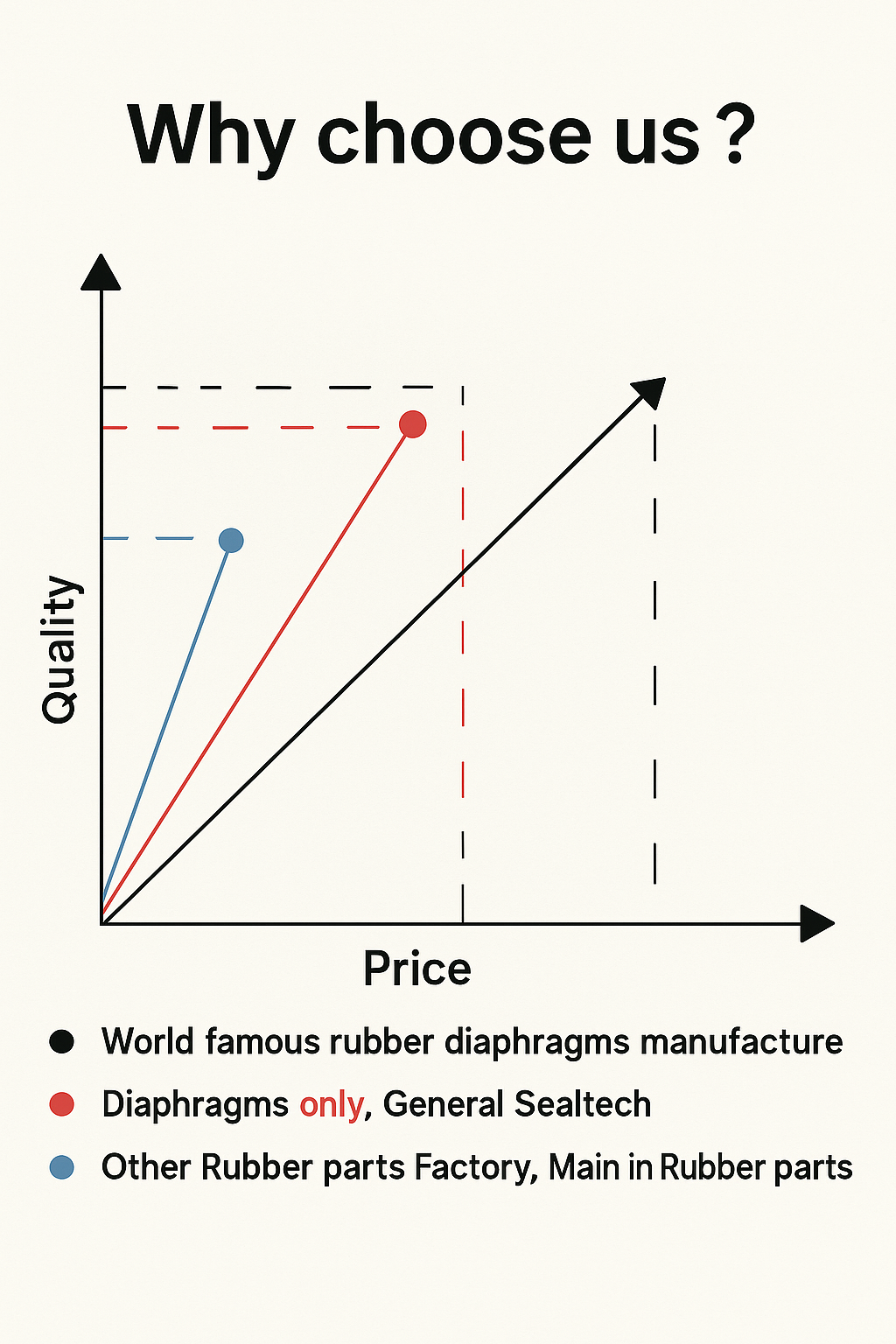

WHY CHOOSE US——–The law of increasing entropy and the production of rubber diaphragms Reflections and Transformation from 20+ Years of Diaphragm Production

We have been producing rubber diaphragms for over two decades. Since last year, due to increasing business volume, we’ve started to feel the pressure. On the surface, it seems that price competition and higher quality demands are the main challenges. But in reality, what troubles us most is management—managing people, technology, orders, and the supply chain.

No business can escape the law of entropy—systems naturally tend toward disorder. We’re increasingly experiencing this internal complexity and chaos.

The Complexity of Rubber Diaphragm Production

Unlike regular rubber products, rubber diaphragm manufacturing becomes significantly more complex due to the incorporation of fabric. For instance, rubber may shrink by 3%, while the fabric may shrink by 5%. So what’s the final shrinkage of the product?

We work with over 20 types of rubber and 20 types of fabric. It means Nitrile rubber diaphragm, Neoprene diaphragm, Silicone diaphragm, or other diaphragm. The combinations are vast, making every case unique and highly variable.

Mold design is another major challenge. Over the past 20 years, we’ve worked with many mold makers, yet issues still arise frequently, causing delays. Mold designers often overlook key factors like fabric thickness or spacing, simply because they lack deep understanding of diaphragm manufacturing processes. They tend to apply generic templates instead of truly customized designs.

The Conflict Between Orders and Raw Materials

Initial customer orders are typically small, yet highly customized. Meanwhile, the minimum order quantities for most raw materials are large, leading to significant waste and rising material diversity.

Moreover, diaphragm products usually require long-term validation inside valves. By the time customers reorder, raw materials have often aged and must be reformulated—adding cost and complexity.

Rethinking and Restructuring

After six months of reflection, we concluded that the design stage and supply chain management are the most crucial parts of diaphragm production. In the future, we plan to outsource manufacturing to different factories, while focusing internally on design, materials, process engineering, and quality assurance.

Since 2023, we’ve brought the mold design process back in-house. Previously, we simply sent a rubber diaphragm drawing to the mold maker and said, “Please make this mold.” Now, we send detailed technical drawings and require full adherence, with any doubts communicated in advance.

Designing a mold takes us about a week—even the simplest cases take 2–3 days. Mold makers, by contrast, often spend less than two hours on design. During our design process, we consider shrinkage, fabric thickness, forming methods, and more. As a result, in recent years, we’ve rarely needed to repair molds. They work immediately, and defective rates are very low.

We’ve applied the same mindset to raw materials. From formulation to fabric selection, we plan and design everything upfront. We even tested this system by sending molds and materials to a factory with no diaphragm experience. With our process sheets, they still produced qualified diaphragms. This validation was extremely rewarding.

Thus, we are transforming from a Rubber diaphragm manufacturer into a supply chain management company, focusing on diaphragm design, materials, process engineering, and testing.

This is a bold step, but it greatly benefits many of our overseas peers. Diaphragm production is a niche field—materials, mold design, and processes are real challenges for many. We’re happy to offer support in these areas.

Facing the law of entropy, we chose to cut and rebuild from where the chaos was most concentrated.

In the next five years, Rubber diaphragm supply chain management will be our strategic direction.