Long service life, can accurately perform synchronous operation with other control components, ensure pulse of compressed air blowing. Even under extremely poor working conditions, can guarantee their normal work and long service life.

1. A kind of mechanical component, used in solenoid valve

2. High temperature resistance

3. Corrosion resistance

4. Long service life

5. Small order accepted

6. Factory direct sales

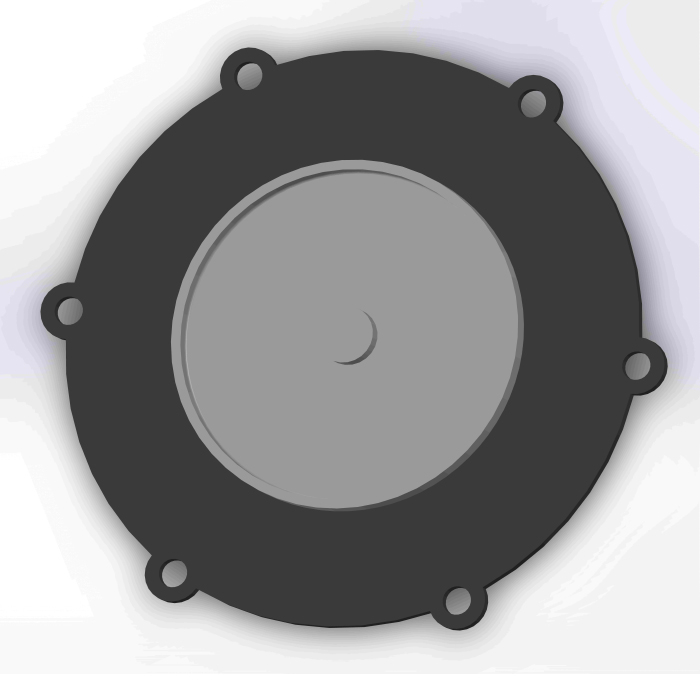

solenoid valve diaphragm

1. Solenoid pulse valve diaphragms act as a barrier or seal within the valve, isolating the different chambers of the valve from each other. This isolation is essential for the proper functioning of the valve, allowing it to control the flow of air or gas.

2. In dust collector systems, solenoid pulse valves are often used for pulse jet cleaning. The diaphragm is a critical component of this process. When the solenoid coil is energized, it causes the diaphragm to flex or lift, creating a temporary opening that allows a high-pressure pulse of air to be released into the filter bags.

3. Solenoid pulse valve diaphragms control the airflow within the valve by opening and closing in response to electrical signals from the solenoid coil. This control mechanism is vital for regulating the timing and intensity of the pulse jet cleaning process, optimizing the efficiency of the dust collection system.

4. Diaphragms must be made from durable and resilient materials to withstand the mechanical stresses associated with frequent pulsing and the potential presence of dust particles in the airflow. Additionally, they need to be resistant to the specific environmental conditions and chemicals present in the system.

What types of fluids can Solenoid Pulse Valve Diaphragms handle?

Solenoid pulse valve diaphragms are designed to handle various fluids:

Compressed Air: Solenoid pulse valves are commonly used with compressed air systems. The diaphragms are designed to handle the pressure and flow of compressed air, which is crucial for the pulse jet cleaning process in dust collector systems.

Inert Gases: Some applications may involve the use of inert gases, such as nitrogen or carbon dioxide. Solenoid pulse valve diaphragms are often compatible with these gases, provided that the materials used in the diaphragm construction are suitable for the specific gas.

Industrial Gases: Depending on the application, solenoid pulse valve diaphragms may be used with various industrial gases used in manufacturing processes. The diaphragm material must be compatible with the specific gas to ensure proper functionality and durability.

Dust-Laden Air: In dust collector systems, solenoid pulse valves are exposed to air containing dust particles. The diaphragms should be resistant to abrasion and damage caused by these particles to maintain reliable operation over time.

Solenoid Pulse Valve Diaphragms

What are the advantages of using a Solenoid Pulse Valve Diaphragm?

1. High accuracy and reliability: Solenoid pulse valves have consistent valve actuation, increasing the accuracy of the flow control. This ensures the system works reliably and in sync with the automation process.

2. Low maintenance: The diaphragm ensures that the solenoid pulse valve is highly resistant to clogging and build-up, reducing the need for frequent maintenance cycles.

3. Smooth operation: Solenoid pulse valve diaphragms can produce a smooth flow with no jolts or jerks, providing a better user experience.

4. Energy efficiency: Diaphragms enable solenoid pulse valves to use less energy when opening and closing the valve, saving the user money in the long run.

5. Long life: The diaphragm of a solenoid pulse valve is designed to provide great resistance against damage, making the valves longer lasting than traditional devices.

How does a Solenoid Pulse Valve Diaphragm compare to other types of diaphragms?

A solenoid pulse valve diaphragm distinguishes itself from other types of diaphragms, particularly in the context of dust collector systems and pulse jet cleaning applications.

Unlike traditional diaphragms, solenoid pulse valve diaphragms are designed for quick and precise response to electrical signals, facilitating efficient control of high-pressure pulses of air essential for dust removal. Their construction from durable materials ensures resilience to wear and tear in industrial environments, offering a longer service life.

Compared to other diaphragm types, solenoid pulse valve diaphragms excel in providing reliable, energy-efficient, and easily maintainable solutions for optimizing the performance of dust collection systems, making them a preferred choice in applications where effective dust filtration is paramount.

Pulse Valve Manufacturer – Diaphragm Solenoid Valve China

General Sealtech is a reputable pulse valve manufacturer in China specializing in industrial diaphragm solenoid valves. Our valves are meticulously crafted to respond rapidly and function seamlessly in dust collectors, pneumatic systems, filter cleaning equipment, etc. Specifically intended for OEM applications, these valves find their use in cement, power, steel, pharmaceutical, food processing industries, etc. and many more.

Pulse valves are used to clean filters and maintain air flow in a system by releasing short bursts of compressed air. The pulse valves pulse diaphragm is flexible andopens and closes rapidly to respond to the solenoid signals. The diaphragm’s quality and endurance are crucial to valve function and life span within extreme settings.