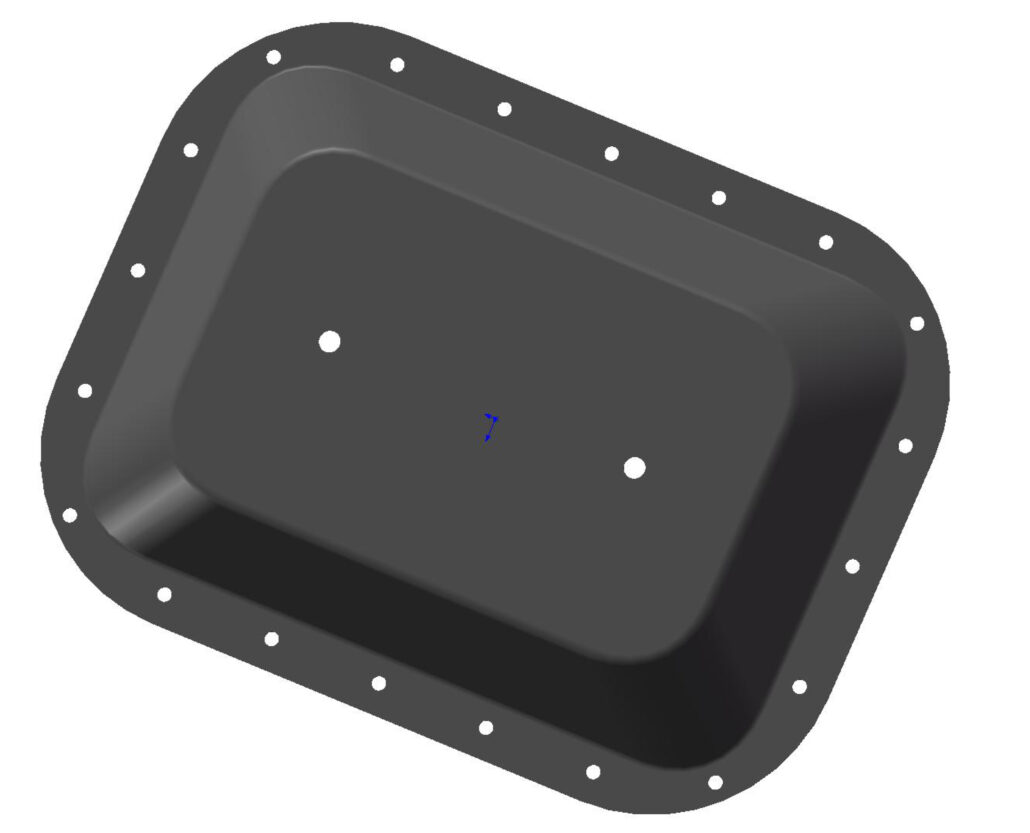

GAS METER DIAPHRAGM

Diaphragm gas meters are the most common type of gas meter, regularly seen in residential and small industrial properties.

Fabric reinforcement is usually required when pressure differentials exceeded 5 psi across the diaphragm. Some applications might require elastomeric coatings on both sides of the fabric. Fabric and elastomer are two of the main materials used in molding or fabricating the diaphragm seals. All kind of high-performance rubber materials is working always under the standard of ASTM d-2000 specifications. The fabric actually is the key components for diaphragm seals which used under pressure and movement and the supply from our local textile industries.

We pride ourselves on our mixing and molding technology, ensuring your rubber products are of uniform quality and free from contamination. Our rubber compounds are formulated to ensure we can meet the exact requirements of your application.

Whether you require natural rubber, Nitrile, Silicone or specific formulae, please do not hesitate to contact us for a no obligation discussion and quotation.

gas meter diaphragm 3D, idiaphragm.com

G1.6 rubber Diaphragm, gas meter diaphragm

Diaphragm Gas Meter – China Diaphragm Gas Meter Manufacturers

As a trusted China-based manufacturer, General Sealtech specializes in high-performance diaphragm components for gas meters. Diaphragm gas meters are the most common type used in residential and small industrial settings. These precision parts are essential for accurate metering and long-lasting operation in varying pressure environments.

Reliable Diaphragm Engineering for Meter Accuracy

Our gas meter diaphragms are crafted with fabric reinforcement, especially necessary when pressure differentials exceed approximately 5 psi. Some applications may benefit from elastomeric coatings on both sides of the fabric to enhance sealing performance. We utilize high-performance rubber materials that comply with ASTM D 2000 standards and partner with local textile industries to source key fabric reinforcements. Our advanced mixing and molding processes ensure finished diaphragms are uniform, free of contamination, and specifically tailored to application requirements. Whether your needs call for natural rubber, nitrile, silicone, or custom formulations, we work with you to develop the ideal compound mix.