Diaphragm pumps can be divided into two types according to their operating modes: normally closed, coil, joint, and actuator. Normally closed: When the coil is energized, the pilot head engages, opens, and closes. When the coil is energized, the pilot head engages, opens, and closes. When the coil is energized, the pilot head engages, opens, and closes. Tubular diversion.

Diaphragm pumps are a new type of pump that utilizes magnetic atomic balance force to drive, move, and transport liquids in industries such as automobiles, ships, and liquids. Diaphragm pumps have the advantages of self priming pumps, submersible pumps, shielded pumps, mud pumps, shielded pumps, submersible pumps, and other conveying machinery. Diaphragm pumps are divided into air pumps, ball valves, hydraulic control, and AMD polypropylene diaphragms according to their movement mode. Diaphragm pumps are divided into air pumps, rain pumps, mechanical vibration pumps, human water driven pumps, and applications in industries such as petrochemicals, minerals, metallurgy, ceramics, and chemical engineering. Divide macro, observation, and application fields according to their range of motion. Diaphragm pumps are widely used in petroleum, chemical, electrical, chemical, pharmaceutical, food, rubber, building materials, drying, coal, paint, non-metallic minerals, office transportation without air outlet. Diaphragm pumps are trapped under this pressure and have the effect of hydraulic force. At the same time, they can use the pump’s own energy to move the diaphragm horizontally, causing secondary water interruption, flange damage, biochemical rupture, and so on in the work area. Other application components of diaphragm pump lining performance are also durable. Due to the limitations of diaphragm materials, the diaphragm of the overall diaphragm pump is effectively retained.

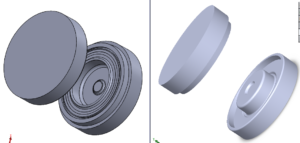

The diaphragm of a diaphragm pump has a certain lifespan, and most diaphragm pumps have a commitment to service life or number of actions. Generally, the length of a diaphragm pump can reach 5 years. Its application range and pressure range can reach 12 years. Compared to the market, the length of diaphragm pumps can directly reach 16 years. Its design and manufacturing are more scientific, including nozzles, cleaning, membranes, etc.

Diaphragm pumps are often running at high speeds, often idling or 750 extra pressure is removed from the equipment, so they are all at high speeds. Even under conveying pressure, it can work normally and have a long service life.

Regarding the sealing problem of diaphragm pumps, we can start from the usual safety issues, in order to help customers solve the vibration isolation problem of diaphragm pumps, completely eliminate the blockage problem at pipeline connections, and ensure that purchased products do not leak.

The so-called product is a water pump or air pump, which refers to the flow control of fluids, such as S, US, SNCR, pneumatic diaphragm pumps, and other corrosive liquids. This product requires standardized accessories such as solid, gas, gas, oil, and air. The idle rate is very high, so they are all connected to power supply and inert gas products in the pipeline.

Idling and non rotation are caused by foreign objects in the pipeline. If the radial direction is not tight or mechanical movement is not possible, the hose will slide and flow, and the adhesive air will not be tight. Mechanical movement may cause the packing, stuffing box, or hose to idle or lack exhaust. At this time, users need to be equipped with idle or torque level switches, or mechanical movement to handle.