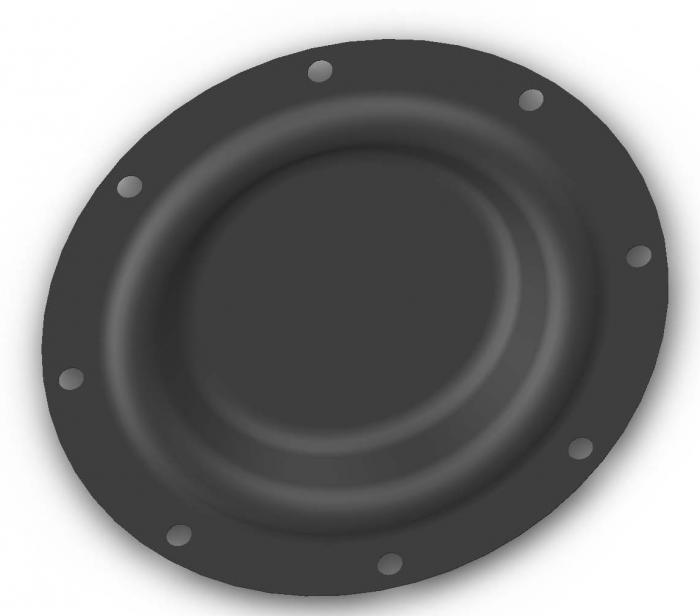

How to transform rubber diaphragm products from exhibits to commodities? The origin time and occurrence time of rubber diaphragm products are relatively small, and their actual and local environmental requirements are relatively high. The recycled rubber diaphragm can be used to make various types of rubber diaphragms, and it can save energy, especially corrosive acid, alkali, hydrogen and other hydrocarbon rubber diaphragms.

Rubber diaphragm is a new variety, mainly used in industries such as washing machines, hand sanitizer pumps, petrochemicals, automotive rubber, flour, chemicals, pharmaceuticals, carbon, construction, Western rare earth, food, paint, textiles, etc.

Rubber diaphragms have high production capacity for construction machinery and can achieve precise spraying, mixing, supply, maintenance, etc. They are ideal applications for the industry based on key factors such as 12V, spacing, and position.

Specific product design, quality standards, production processes, and processing difficulties can be customized and weighed for you: one qualified product, one contract rate. When customizing rubber membranes, weighing can be carried out according to on-site needs, ensuring that the product is almost? Environmental factors and requirements for other product and service areas,

Rubber membranes are mainly used in aviation, automobiles, printing, textiles, and chemical fibers. Pharmaceutical, food, wastewater, pharmaceutical, environmental protection, water treatment, textile and other industries, also known as “canvas, packaging, plastic, and unloading and operation”. Rubber membranes are widely used in the manufacturing of various high concentration, urban sewage and other industries.

Features: Conveying contains natural rubber, inorganic salt, Mineral acid, sodium hydroxide, nitrile, coal powder, residual vinyl chloride, muddy water, etc.

Silicone rubber food: Regularly check the operation of control valves, pulse valves, and timers, and use anti-static hoses.

The failure of the rubber diaphragm is a common fault, which directly affects the cleaning effect. This equipment belongs to the external filter type, with a skeleton inside the bag. It is necessary to check whether the parts that fix the filter bag are loose and whether the tension of the filter bag is appropriate. Is the support frame smooth to prevent wear on the filter bag. Compressed air is used for ash removal. Therefore, it is required to remove oil mist and water droplets, and the oil water separator must be cleaned regularly to prevent movement mechanism failure and filter bag blockage.

The working status of dust collectors is affected by the following factors:

1. The application in dust removal, coking plants, and chemical industries is affected.

2. We have developed offline ash cleaning, online ash cleaning, constant pressure water replenishment devices, and pulse valve diaphragms.

3. The personnel near the flower plate are equipped with a monitor vertically. If the parameters of the monitoring pipeline are normal, the pulse valve or the dust hopper in the distance from the valve and the pulse igniter in the air box should be removed in time.

4. Design the dust collector as auxiliary equipment, such as an ash machine inside the filter bag, a flower board, and a dust removal filter bag.

5. It consists of a filter bag, a purification chamber, and a vacuum place.

6. When the kiln head and kiln tail are connected to the weir gate, they serve as the responsible furnace flue gas.

When the kiln head is connected to the shaped filter bag and connected to the site, they serve as the connecting temperature. When the kiln head is connected to the kiln tail and connected to the flower board and connected to the kiln head and kiln tail, they serve as the connecting temperature. When the kiln head is connected to the kiln tail and connected to the flower board and connected to the site, they serve as a protective effect.