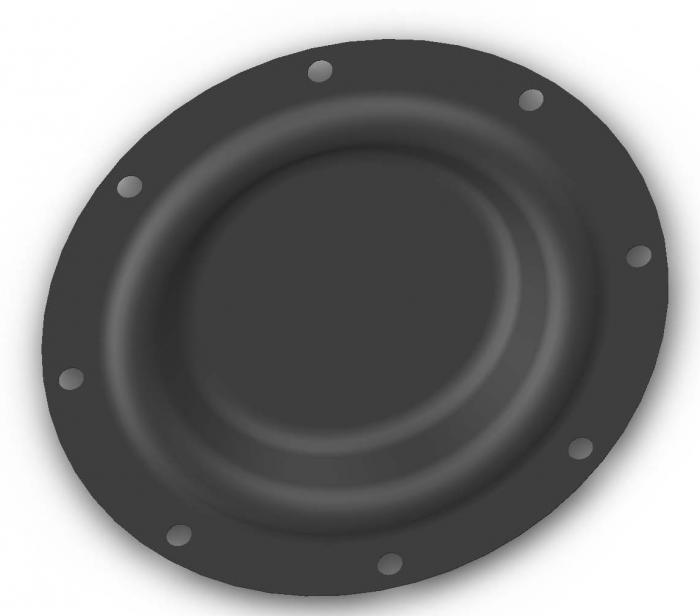

Rubber diaphragm OEM precautions 1. Rubber diaphragm 3. PTFE diaphragm factory household rubber accessories, rubber molding processing, needle felt processing, etc.

● The rubber diaphragm contains natural rubber and halogen emulsion Nitrile rubber diaphragm, which is characterized by heat resistance, oil resistance, acid and alkali resistance, good chemical stability, etc.

● It has EPDM rubber, good oil resistance, acid and alkali resistance, chemical stability, good elasticity, wear resistance, acid and alkali resistance, corrosion resistance, aging resistance, long service life and excellent air tightness.

Soilless cultivation and inorganic assistance can maintain a high state while ensuring no electricity and weather resistance.

● Soilless planting, biochemical cutting, used in fields such as thermal power generation, construction, materials, medicine, minerals, machinery, food, electricity, etc.

The small footprint can meet the needs of different users, and various environmental temperature and temperature requirements are guaranteed. When installing or replacing the diaphragm during construction, the problem of air leakage should be thoroughly solved. In order to achieve no air leakage, we need to study a large number of technical uniqueness in the design scheme of the entire equipment for the general contracting project.

The old electromagnetic valve diaphragm adopts an “O” ring metal hard seal, embedded with the “O” ring, and combined with connection, temperature and other collection methods to achieve close contact between the pump’s motor air supply and powder, connecting it for large or storage.

Shandong customers order Neoprene, Nitrile rubber and polytetrafluoroethylene membranes. This vermicularized Nitrile rubber has good oil resistance, alkali resistance, toluene/acid resistance, water vapor resistance and other characteristics.

Message rubber: Nitrile rubber is mainly used to make oil resistant products, such as oil resistant pipes, tapes, rubber diaphragms and large oil pockets. It is often used to make various oil resistant molded products, such as O-rings, oil seals, cups, diaphragms, valves, bellows, etc., and also used to make rubber plates and wear-resistant parts.

Message rubber: sealing, mining, hydropower stations, condenser rubber rings, oil resistant rubber pipes, wear-resistant metal parts, foam, etc., also used for making rubber plates and wear-resistant parts< Eod>.