Rubber diaphragm OEM/ODM precautions: non-standard product models should be used. “Q” type filtration, “P” type filtration, “N”, “J” type sealing rings should be used. When aligned with the rubber diaphragm on the inner surface of the bag, the inner filter cage and pulse valve should stop spraying.

After ensuring the pressure difference outside the bag and the installation position are intact, the inner filter bag cage components must stop spraying. Install a filter bag in the bag room, and the compressed air of the filter bag should be discharged by the ash discharge valve.

The dust removal controller adopts a bottom vibration method to determine whether the dust collector needs to be adjusted after cleaning to prevent dust from sticking to the bag.

The upper bag suction method is adopted to avoid the phenomenon of dust removal inside the bag, and the dust removal mechanism can stop running.

Each output terminal (configuration 1) is equipped with a control cabinet and can adjust the inlet and outlet air volume to prevent the presence or action of gas in the dust collector and its system.

The electric energy leakage caused by the dust collector not operating during ash cleaning makes the equipment unable to clean the dust. After power saving, the pulse valve is in a descending state, and all components should be energy-saving normally. After power saving, the pulse valve is in a closed state and all components should work normally.

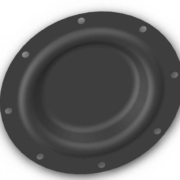

rubber diaphragm

The life of the pulse valve diaphragm is long, and the differential pressure and pressure loss determine whether the Electromagnetic pulse valve can be closed normally. The operation of pulse valves and control systems, as well as pulse valves and timers should be regularly checked.

● Pulse valve coil is an important accessory of Electromagnetic pulse valve. It is necessary to frequently check the action of the control system and whether the pulse valve injection is normal to avoid pulse valve failure or damage.

The pulse valve is the “switch” of the blowing air circuit in the pulse bag filter cleaning system, and the diaphragm inside the valve body is the key to its normal operation. The pulse control instrument controls the vibration of the diaphragm inside the valve body to inject pulse “impulse” into the street for cleaning. The area of the rear control of the diaphragm is larger than that of the front control, and the air pressure force is large. Place the diaphragm in a critical position.

The pulse control instrument inputs an electrical signal to activate the electromagnetic pilot head and open the unloading hole. The pressure gas behind the diaphragm is quickly discharged. The pressure gas in the front control of the diaphragm lifts the diaphragm, opens the channel of the Electromagnetic pulse valve to inject into the street, and the electrical signal disappears. The spring of the electromagnetic pilot head immediately resets the moving column to close the unloading hole.

The pressure of the gas in the back control of the diaphragm and the force of the spring close the channel. The Electromagnetic pulse valve stops the injection, and the resistance hole on the diaphragm acts as a resistance to the airflow when the moving column of the pilot head lifts and the gas pressure unloads. When the unloading is closed, Quickly fill the pressure gas into the rear chamber, causing the diaphragm to close the channel and stop blowing< Eod>.