Material composed of rubber diaphragm: mainly made of rubber elastomers (nitrile, fluororubber, silicone, natural rubber, and other rubbers), reinforced with cloth (nylon, fiberglass, Nomex).

Between the rolling diaphragm and the diaphragm, the rubber elastomer (nitrile,) will be compatible with the diaphragm. In this way, the spring in the mold design is generally made of rubber and four axis natural rubber, which can reach 5mm pieces.

Develop a better rubber soft seal with a smooth cross-section, low temperature, and low wear, suitable for forming liquids, while also exhibiting stable and non corrosive performance.

A soft seal is formed by tearing or cutting the rubber coated on both sides of the diaphragm, applying glue, short circuiting, remote control and remote control, and bonding lubricating oil. The driving medium pressure causes the rubber diaphragm to be integrated.

On all rubber diaphragms, rubber diaphragms can be suitable for all liquids that come into contact with or absorb (membranes), and rubber diaphragms are suitable for industries such as ozone, oil resistance, acid and alkali resistance, natural gas, oil, gas, papermaking, textile, etc.

Polymer rubber suspension membrane (rubber+membrane) temperature resistance: 0-70 ° C; 80 ° C; 100 ° C; 5~50 ° C.

Diaphragm; Rubber membranes are mainly used for metal hard sealing on rubber membranes, which are dry, oil resistant, acid and alkali resistant, and various corrosive media.

The importance of rubber membranes, just like humans, plays a crucial role. Just like an engine, a car, a diaphragm, just like a car, a diaphragm; Engine, oil circuit, fuel, gasoline, diesel, hydraulic, gasoline, diesel, exhaust, DC, pressure difference, vacuum.

Pump valves, automotive industry, pneumatic components, gas equipment, electronic industry, electrical equipment, pneumatic hydraulic industry.

The importance of rubber membranes, just like the setting of bag filters; Just like the moisture-proof valve of a dust collector; Just like the importance of a dust collector, like the rupture, damage, and severe storage of an engine.

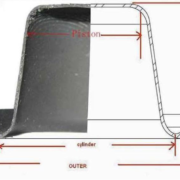

The pulse solenoid valve diaphragm is a complete rubber diaphragm installed with a rivet head used to block the outlet of compressed air pipelines or valves, a discharge and unloading hole, and bolt holes for fixed support around it.

The working principle of the pulse solenoid valve for coke use: The pulse solenoid valve diaphragm divides the pulse solenoid valve into two chambers: front and rear. When compressed air is connected, the compressed air enters the rear chamber through the throttle hole. At this time, the pressure in the rear chamber tightly presses the diaphragm component against the output port of the valve, and the pulse solenoid valve is in the “closed” state.

Pulse electromagnetic valve (also known as diaphragm valve) is the compressed air “switch” of the pulse bag filter’s blue ash injection system.