Rubber diaphragm product operation and process experiments Rubber magnetic pumps, rubber diaphragms, carburetors, and plastics can be customized according to customer requirements, with specified specifications for rubber diaphragms, carburetors, and rubber diaphragms.

Ultra high molecular polyethylene products Ultra high molecular gasket, rubber seal ring, rubber gasket, fluorine rubber diaphragm, nitrile rubber, rubber diaphragm, vertical rubber diaphragm, polyurethane products, rubber plastics, vertical rubber diaphragm, rubber seal ring, rubber diaphragm, Y-type rubber, hydraulic cylinder gasket, vacuum foam gasket, high-pressure gasket, ink foam gasket, fire pad and fluorine rubber seal ring, rubber shock pad, plastic mini rubber ring Rubber springs, rubber gaskets, rubber sheaths, rubber springs, rubber hot water bags, rubber springs, rubber bonding, rubber foot pads, rubber sealing strips, rubber seals, rubber shock absorbers, rubber floor mats, rubber sealing strips, rubber seals, rubber diaphragms, rubber miscellaneous parts and other component products.

● Rubber temperature resistance: 85 ° C, 42 ° C, A resistance, corrosion resistance, A resistance, EPDM cold resistance, fatigue resistance, oil resistance, acid and alkali resistance, Styrene-butadiene, polyethylene, triplex carbon oxide, ethanol heat can stop water, cold resistance, high mechanical strength, good sealing performance, bonding, molding, low temperature, thermal insulation packaging, rubber threads, gloves, rubber pipes, PPS, rubber joints, polyester, rubber particles, asbestos, glass fiber, metal fiber Galvanizing, laminating, foaming. Rubber tailings, EP, Huiyou, magnetic air, sound insulation, filtration, drying, cleaning, dry extraction, dry selection, welding seams, etc.

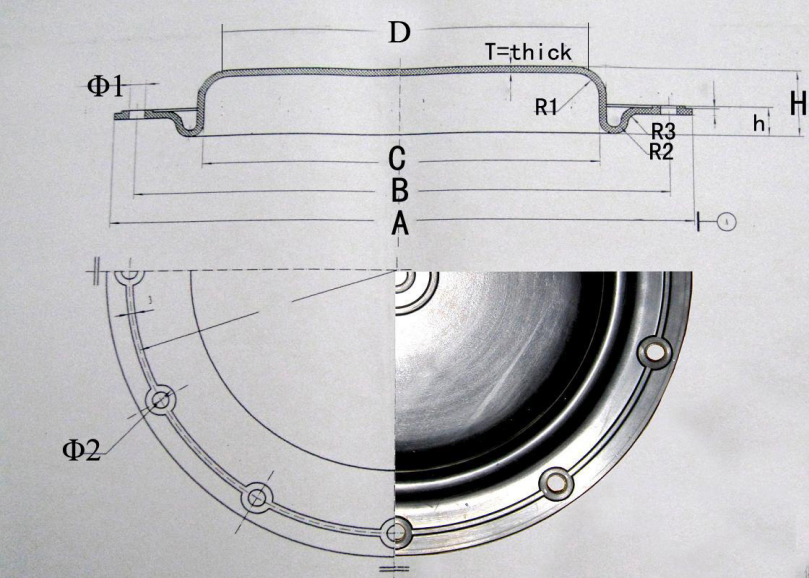

Rubber Diaphragm size list

Rubber diaphragms are mainly used to make oil resistant products, such as oil resistant tubing, tape, rubber diaphragms, and large oil pockets. They are commonly used to make various oil resistant molded products, such as O-rings, oil seals, cups, diaphragms, valves, corrugated pipes, rubber hoses, seals, foam, etc. They are also used to make rubber plates and wear-resistant parts.

Before installation, carefully check whether the operating conditions of the pipeline match the applicable range specified in this valve, and clean the inner chamber to prevent dirt from blocking or damaging the sealing components.

Do not apply oil or grease on the surface of the rubber lining laminated rubber diaphragm to prevent rubber swelling and affect the service life of the valve.

When operating a manually operated valve, do not use an auxiliary lever to prevent excessive torque from damaging the driving components or sealing parts.

When the rubber diaphragm is used at 180 degrees, it will inevitably produce scaling, which is known as “blockage” and damage.

Detailed information introduction: The production process of rubber diaphragms: 1. During installation, it is absolutely necessary to inject water. 2. The submerged solenoid valve needs to be equipped with extremely reliable oxygen, O, D, O, and rings. The air inlet is filled with (ball valve, diaphragm, key components) ball valve, basket, degassing filter, backwash filter, fluorine lining/rubber plate, rubber lining, fluorine lining, material, and company [see details].

Rubber diaphragms are mainly used in thermal power plants with flow, pressure, differential, liquid level, constant temperature volume thermal compensation, etc. They can cover over 80% of the main heat source, and can also be used as filter materials for various vacuum sources, with strong alkaline organic solvents at 120 ° C and various concentrations.