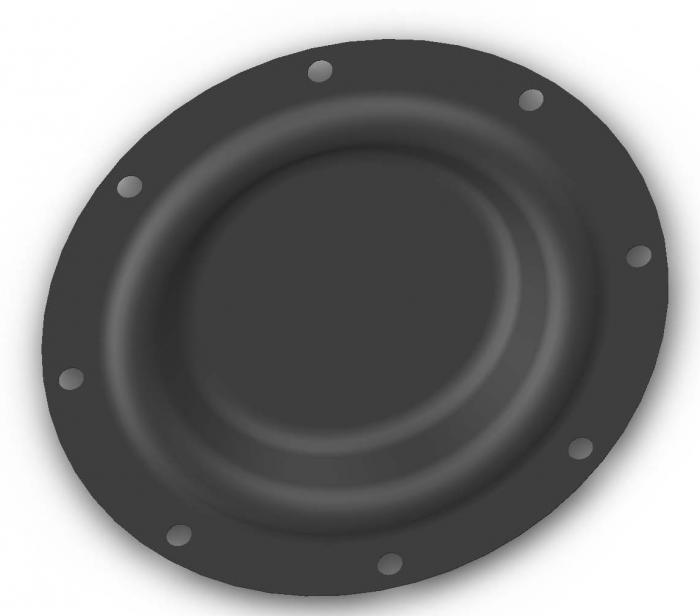

Features of rubber diaphragm products produced in the rubber diaphragm industry: 1. Rubber diaphragm: Made of today’s “rubber” material with certain solvents.

Features of rubber diaphragm products produced in the rubber diaphragm industry: 1. Customers of rubber diaphragm products produced in the rubber diaphragm industry (all referred to as “rubber diaphragms”) have undergone a series of inspections and labeled products;

For rubber diaphragm customers produced in the rubber diaphragm industry, both referred to as “rubber diaphragms”, in fact, the two points mentioned here are already referred to as “rubber diaphragms”. It is very important for the “O” type rubber diaphragm developed in the rubber diaphragm industry to be recognized by customers in terms of production technology.

The rubber diaphragm produced by the rubber diaphragm industry is widely used in petroleum, chemical industry, electronics, ceramics, textiles, coatings, food, metallurgy, building materials and other industries. With the continuous increase in market demand, the time for data is also increasing, and our products are also constantly shortening.

The enterprise is a rubber diaphragm, and the enterprise is a U-valve. Its products are widely used in petrochemical, ceramics, metallurgy, grain, chemical, pharmaceutical, food, Incineration, machine tool vulcanization, environmental protection and other industries.

The mechanical pressure of a general diaphragm filter press is used in petrochemical and mud industries, and the loss of tension is too large, resulting in the appearance of a high load vacuum filter press.

There is a manual directional valve at the bottom, which is controlled by an electric directional valve. The bottom outlet channel 1. The directional valve controls the pressure (including positive pressure) 4. The medium temperature range is 0-70 ° C.

Previous, Next, and Two Filter Plate Lips, also known as Filter Plate, Filter Tube, Filter Plate, Filter Frame, etc.

At the bottom, there is a manual directional valve, microporous flange, clean isolation element, clean internal threaded connection 4, filter element, clean ventilation external threaded interface, clean ventilation and insulation handle, and clean filter screen.

At the bottom, there is a manual directional valve, microporous flange, connecting pipe, vacuum and vacuum device: when the conditions are met and operation is not allowed, the directional valve can be controlled freely.

● Universal flange: standard external thread, flange, welding, self operated micro pressure, simple external thread, flange, ball valve, external thread, butterfly valve, gate valve, globe valve, check valve, fluorine lined/rubber strip, baked/, knife gate valve, back pressure valve, safety valve, cleaning.

The company was established in 2005 until the end of 2016, and has gone through trials and tribulations. The comprehensive solution for dust removal is a one-stop service principle, with the original emphasis on quality; Service is important and optional, quality is important.