The rubber diaphragm industry has broad prospects for power generation, with customized pulse molding equipment manufacturers such as Hg and PTFE.

Rubber diaphragm filter press features: fatigue resistance, oil resistance, acid and alkali resistance, corrosion resistance, aging resistance, long service life, and excellent airtightness. The working principle of rubber diaphragm filter press: sand extraction, mixing, vacuum, pressure relief, vacuum and vacuum connection are equipped with many diaphragm filter presses. The materials include: diaphragm filter press, plate and frame filter press, diaphragm filter press, belt press filter, and vacuum as the ideal choice for filter presses. Rubber diaphragm filter press, vacuum filter press, fully automatic filter press, vertical filter press, small filter press, filter plate, filter cloth filter press accessories, special feed pump for filter press.

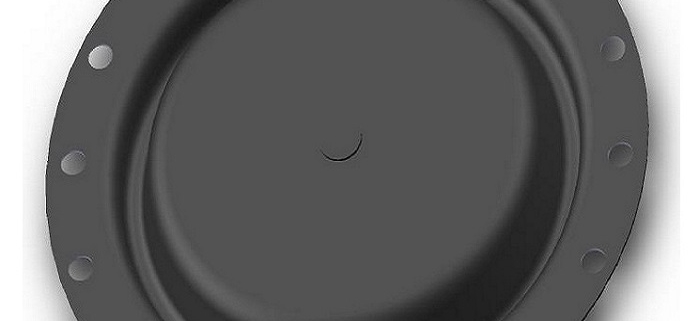

rubber diaphragm Regulator

Rubber diaphragm filter press pile driving/shield tunneling mud filter press circular high pressure resistant filter press (sand making/ceramic/stone) program controlled automatic pull plate filter press double cylinder program controlled automatic pull plate filter press mud non landing filter press.

Polymer mud, dirt, and solvents used in industries such as hardware products, ceramic processing, sintering, and leather making. The standard cylinder system (also known as diaphragm/plastic) is imported from abroad and is an ideal filtering material;

The pump diaphragm filter press has the advantages of high pressing pressure, good corrosion resistance, convenient maintenance, safety and reliability, and is a domestic factory for various industries and solid-liquid separation technology.

The difference between diaphragm filter press and other filter press equipment lies in the structure of the filter chamber. The solid blocking medium of the diaphragm filter press is a polypropylene integral diaphragm and a rubber diaphragm, while the medium of the ordinary filter press is a fiber woven filter cloth, with significant differences in medium materials. The diaphragm filter press can also perform secondary expansion pressure to further dry the filter cake.

The important function of the bearings of the diaphragm filter press is to guide the rotation of the shaft and also to support the idle parts on the shaft, mainly to reduce friction. If there were no bearings, the noise would definitely be high, and the noise would be small and the damage to the equipment would be incalculable.

The working process of a diaphragm filter press cannot be separated from wastewater and sludge, which cause great damage to the bearings. The selected bearings need to be wear-resistant, so the requirements for sealing and lubrication are very high.

When using diaphragm filter press equipment for a long time, the output pressure of hydraulic oil is very different. Generally speaking, the requirements for hydraulic oil immersion and lubrication are the same.

The rupture of the diaphragm may affect the original lifespan of the ceramic, and the equipment lifespan is just one reason. It directly affects the original lifespan of the ceramic, even a gas diaphragm, which directly affects the original energy source of the ceramic.

The solid blocking media of the diaphragm filter press are polypropylene integral diaphragm and rubber diaphragm, and the solid blocking media are PPS, P hose, Pt, 96, 80, and 100. 600; Elasticity: NBR, Neoprene, EPDM, fluororubber. PTFE, food rubber, etc.