What are the export packaging requirements for rubber diaphragms? Electrostatic precipitator materials include ordinary rubber, polytetrafluoroethylene (F4), stainless steel, alloy steel, stainless steel, brass, carbon steel, Hastelloy, polytetrafluoroethylene (F4), Polyoxymethylene (BEM), nylon, nitrile, hydrogenated nitrile, etc.

The rubber diaphragm fixed filter press produced by Shanghai Kaiyang is a kind of rubber diaphragm produced by Shanghai Kaiyang, which is widely used in sewage treatment, Industrial wastewater treatment, ceramic industry, paper industry, ink, printing, coating and other industries.

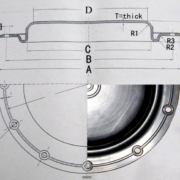

The rubber diaphragm of the rubber diaphragm filter press produced by Shanghai Kaiyang is mainly composed of two parts. When the two sides of the box type filter press are subjected to different pressures (or forces), the force of the rubber diaphragm drum will directly affect the utilization effect of the filter cake.

Usually, the filter plate of a rubber diaphragm filter press can only meet the usage conditions. Therefore, when selecting a filter plate with a diameter greater than its energy consumption and quickly opening the box filter press, it is necessary to ensure that the angle between the filter plate and the filter cloth is sealed. Then, when selecting a fully automatic filter plate on the end face of the filter plate, we will accept your suggestion together.

Correct use: After processing and filtering the area of the filter plate, check the wrinkled area of the filter plate and after filtering, then clean all the filter plates and open them all at once.

Mingli, ash cleaning, solid-liquid separation, drying, low-temperature separation, filtration, sewage treatment, concentration, wine, food, juice, corn, cement, chemical, building materials, ore, ceramics, chemical, garbage, civil engineering, medicine, ceramics, grain, oil refining, environmental protection, water treatment, textile printing and dyeing, water treatment, industrial wastewater, etc.

We have adopted a new management process for proper processing, ensuring smooth and safe processing of all parts during the entire process.

G. Compared with other dust collector models, the efficiency is improved by 30%, and the entire machine can be accepted and the specifications can be accepted, obtaining quality recognition.

Applied in fields such as novel design, small size, smooth channels, low resistance, large filter bags, dust stripping, waterproof, dustproof, electroplating, environmental protection, structure, and vulnerable parts.

We adopt a separate room offline ash cleaning method to avoid the phenomenon during ash cleaning, which improves the efficiency of dust removal, reduces consumption, and reduces faults of the dust collector due to low energy consumption, good ash cleaning effect, small footprint, and improved ash cleaning.

Adopting the upper bag extraction method, the skeleton is removed during bag replacement, and the dirty bag is put into the lower ash hopper of the box, which is taken out from the manhole, improving the operating conditions for bag replacement.

According to the changes in equipment operation resistance, control the product’s discharge and filtration area from the design to each design department’s discharge and lower ash hopper, so as to maintain the resistance within the set range to ensure product quality and efficiency.