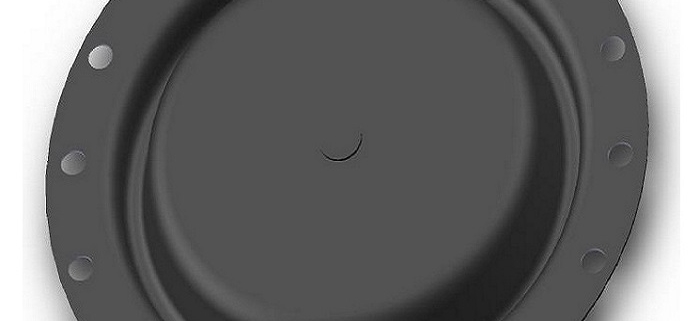

What Equipment Can Rubber Diaphragm Be Used For And How They Work

Rubber diaphragm is flexible components made of rubber or elastomeric materials. They are used in various applications to convert mechanical forces or pressure differentials into linear or reciprocating motion. Here are some common equipment and systems where rubber diaphragms are utilized:

Pumps: Rubber diaphragms are widely used in pumps, such as diaphragm pumps and air-operated double diaphragm (AODD) pumps. They act as a barrier between two chambers, allowing the displacement of fluids or gases. As the diaphragm flexes back and forth, it creates suction and pressure, facilitating the pumping action.

Valves: Rubber diaphragms are employed in different types of valves, including diaphragm valves and control valves. In these applications, the diaphragm acts as a movable barrier that regulates the flow of fluids or gases. By flexing the diaphragm, the valve opens or closes, controlling the passage of the medium.

Actuators: Rubber diaphragms are used in actuators, such as pneumatic and hydraulic actuators. These diaphragms convert fluid pressure into mechanical motion to operate various mechanisms, such as valve stems, levers, or linkages. By controlling the pressure on either side of the diaphragm, the actuator can produce linear or reciprocating motion.

Pressure Regulators: Rubber diaphragms are also utilized in pressure regulators to maintain consistent pressure in a system. The diaphragm reacts to pressure changes and adjusts the position of a valve or a pilot system to control the flow or release of fluid or gas, thus stabilizing the pressure.

Sensors: Rubber diaphragms can be used in pressure sensors or transducers to measure and detect pressure changes. When subjected to pressure, the diaphragm deforms, and the displacement is converted into an electrical signal or mechanical motion, enabling pressure measurement.

The working principle of a rubber diaphragm involves its elasticity and flexibility. When subjected to pressure or mechanical forces, the diaphragm deforms or flexes, allowing the transfer of energy or movement. The material properties of the rubber, such as its elasticity and durability, enable the diaphragm to withstand repeated flexing and maintain its functionality over time.

It’s important to note that the specific design and functionality of rubber diaphragm may vary depending on the application and industry. The selection of the diaphragm material, thickness, and shape is determined by factors such as the pressure range, chemical compatibility, temperature, and durability requirements of the specific equipment or system.