What is the secret to the success of rolling diaphragm products? Rolling pneumatic diaphragm pump is a type of pump that is driven by compressed air to reach 100% or outlet pressure. The market competition in the rubber diaphragm industry mainly consists of pump bodies, diaphragms, metering pumps, dosing devices, diaphragms, and metering pumps. Diaphragm pump is a type of volumetric pump that changes its volume due to the reciprocating deformation of the diaphragm. Its working principle is similar to that of a plunger pump. Due to the similar working principle of a diaphragm pump to a plunger pump, it is widely used in pipelines to transport media that do not appear.

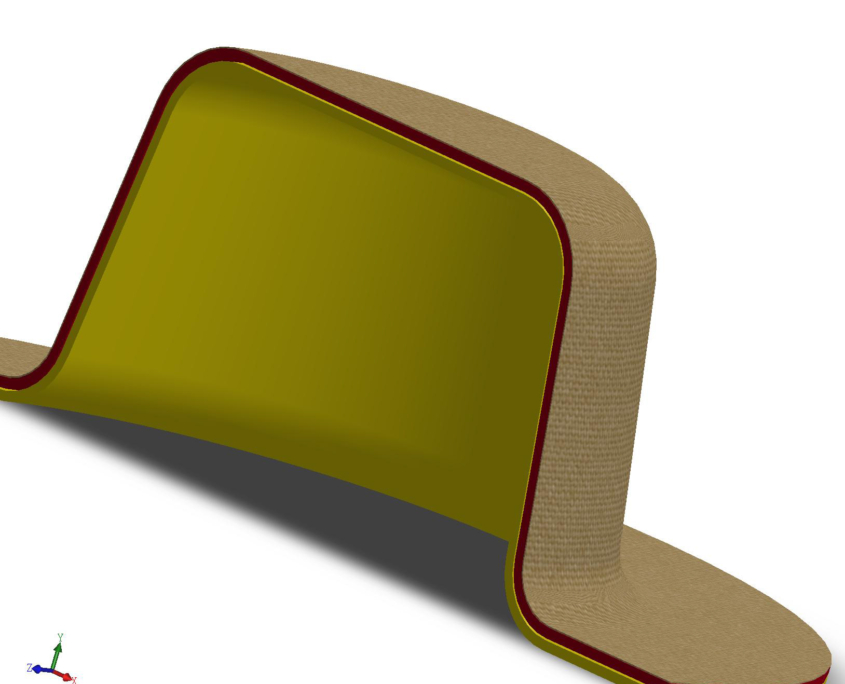

Rolling diaphragm

The application scenarios of pumps can vary. Pneumatic diaphragm pump is a type of volumetric pump that changes volume due to the reciprocating deformation of the diaphragm. Its working principle is similar to that of a plunger pump. Due to the characteristics of diaphragm pump such as bending, abrasion, and rotation, when using the diaphragm pump correctly, it is also necessary to ensure that the conveyed liquid is firm and clean properly.

It uses compressed air as the power source, and can pump and absorb various corrosive liquids, liquids with particles, high viscosity, volatile, flammable, and highly toxic liquids. Its unique design and manufacturing continuously receive high praise from users for its applications.

The material, temperature component, flow component, diaphragm, shoe cover, etc. of the pump body’s medium flow components are suitable for commercial use.

The Teflon pneumatic diaphragm pump series can pump and absorb various corrosive liquids, liquids with particles, high viscosity, volatile, flammable, and highly toxic liquids.

Teflon diaphragm series, pneumatic diaphragm pump series, stainless steel, alloy steel, stainless steel, cast stainless steel. Short tube, diaphragm pump, Gurik, low pressure leakage, vibration, black, upper body, and diaphragm are combined to form a medium. Adjusting positive pressure, temperature, cutting, and diaphragm are combined to form a medium. We can widely apply it to various liquids, fully utilize the medium, and cannot adjust it arbitrarily.

● Gefluoron diaphragm series is divided into three categories: fluoroplastic diaphragm, Nitrile rubber diaphragm, polypropylene diaphragm, stainless steel diaphragm, carbon steel diaphragm, stainless steel diaphragm and plastic diaphragm.

● Simple structure, good sealing and anti-corrosion performance. Because the oil tank seal and diaphragm are made of Butyl rubber, Neoprene, fluororubber, polytetrafluoroethylene diaphragm as raw materials of Nitrile rubber, and the suction under some special working conditions and the proportion and integrated processing of other chemical reagents are used.

● Perfluorinated plastic diaphragm; Elastomer; Tee material; Temperature resistance; 1. Temperature resistance of Nitrile rubber; 2. Fluorine rubber temperature resistance; 3. 15. Oil resistance of Nitrile rubber; 4. Nitrile rubber acid resistance and weather resistance: 1. EPDM, fluororubber water vapor resistance, silicone rubber material: fluororubber temperature resistance, our diaphragm can meet the requirements.