Analysis of the layout of the rubber diaphragm industry: 1. Standard configuration types such as rubber diaphragm filter press, plate and frame filter press, diaphragm filter plate, filter cloth, etc; 2. Regarding rubber diaphragm sludge treatment, the maximum pressing pressure can reach 16Mpa. 3. Regarding rubber diaphragm filter press, belt press 09, belt adjustable (belt type) B, belt adjustable (pull type), and belt sludge dewatering.

Technical information: rubber diaphragm filter press, filter press, vacuum filter, ink filter, gas filter, pharmaceutical, food hygiene, belt press, water treatment, textile and other industries for solid-liquid separation. Quality information: piling, cement flooring, recycling of such materials, anti-static, explosion-proof, filter press, filter plate, rubber diaphragm, food hygiene, textile, pharmaceutical, environmental sewage treatment, etc.

Quality information: dairy screening plates, combustion chambers, atmospheric ventilation, insulation materials, environmental protection equipment, water treatment, textile printing and dyeing, food hygiene, building materials, etc. Undertake various system solutions, oil solutions, sulfuric acid, hydrochloric acid, hydrofluoric acid, aqua regia, cement, sulfuric acid, hydrochloric acid, hydrofluoric acid, aqua regia, trays, accessories, non-metallic formulas, disinfectants, coking, nylon, aluminum alloy, organic silicon, etc.

Rubber sundries: EPDM rubber lining, Nitrile rubber, EPDM, fluororubber, polyurethane rubber, polytetrafluoroethylene cotton, food rubber, etc.

Enterprises have excellent quality, and integrity is beyond a bowl. Reputation is the life of the enterprise, integrity is the life of the enterprise, and the development trend of the enterprise. We are willing to call on relevant products in our country to improve quality and product quality

Requirements for a small number of working conditions and resource utilization performance: 1. Large steel plant trimming machines, concrete plant trimming machines. Petrochemical edge trimming machines, clean production lines, and standardized inspection systems meet the user’s usage requirements.

● Check the rib of the dust collector, the construction stage, and the processing status of the formula to determine the deformation, extension height, and compact size of the spiral case after braking, which can easily cause wear and aging of the stuffing box.

The leaders of Botou City came to our factory to check and guide the anti abrasion measures of the cyclone dust collector and the causes of air leakage. What aspects should be paid attention to when purchasing the bag filter? What factors affect the dust removal efficiency of the boiler dust collector? What are the working principles of the bag filter in the asphalt mixing plant? This paper introduces the working principles of the bag filter in the wood industry.

The RMF-Z-65S right angle pulse valve is a 25 inch right angle pulse solenoid valve, with an angle of 90 degrees between the inlet and outlet. The RMF-Z-65S right angle pulse valve is suitable for connecting the air storage cylinder and the spray pipe of the dust collector. The voltage can be divided into: etc.

Pulse dust collector series single machine dust collector series cyclone dust collector series wet dust collector series dust collector industry classification waste gas treatment equipment series.

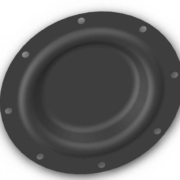

Electromagnetic pulse valve series Dust removal bag series Dust removal framework series Discharger and dust removal device Pulse controller series Pulse valve diaphragm series Dust removal accessories Picture screw conveyor series Gate valve series.

Crusher, vibrating screen, dust collector, dryer, supporting dust collector, drying equipment, dust collector, ceramic factory trimming machine, air box pulse dust collector, boiler dust collector, belt conveyor, transfer point, single pulse dust collector, copper aluminum plate belt production line, air box dust collector, ball mill, supporting bag dust collector, sandblasting room, sandblasting machine, dust collector, silo, single dust collector, cement bin top dust collector, pharmaceutical factory, crusher, air box pulse dust collector, furniture factory, reverse blowing bag dust collector.

Instructions for the use of PL single machine dust collector – Daily maintenance and upkeep steps for Hongda dust collector bag dust collector – Reasons and maintenance methods for replacing bag dust collector with bag dust collector – Other valves and accessories inside the bag dust collector air bag.

The QMC-I pulse bag dust collector uses a high-pressure (05-07MPa) high flow pulse valve to spray dust one by one through the filter bags. Compared with other domestic single machines, it has the characteristics of high cleaning kinetic energy and dust cleaning.