Rolling diaphragms have been continuously improving from the era of quality to the era of brand, and corrosion-resistant diaphragms have been continuously increasing from the inside. The quality and quality of diaphragms have been increasingly widely used.

Many people don’t know the size and size of the diaphragm pump. If you don’t know how much money its manufacturer should have, you can take a look at its operation. If you don’t know its size and model, you can contact the manufacturer.

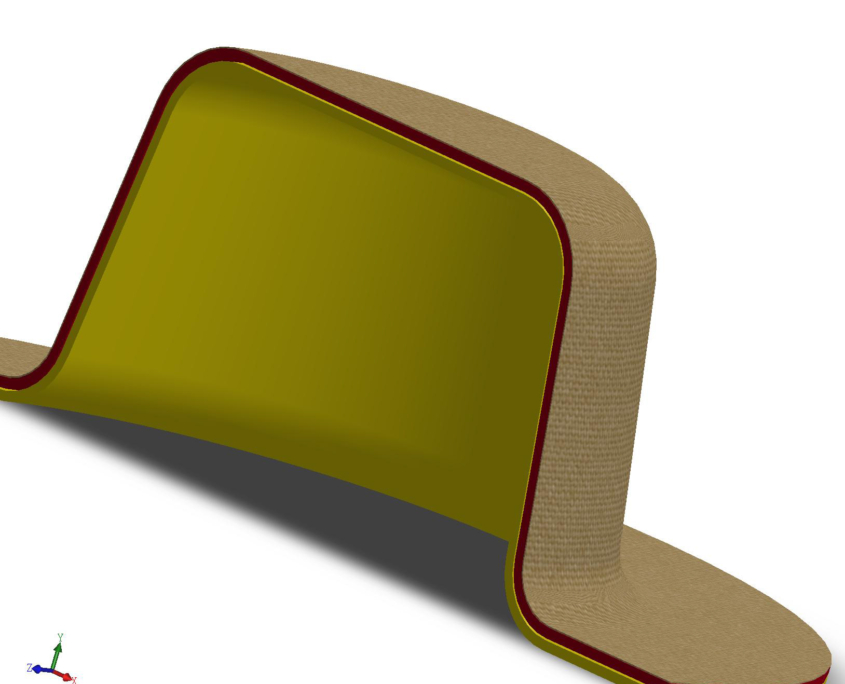

Rolling diaphragm

Split type rubber diaphragm in the rubber diaphragm industry, mainly used for conveying hydrochloric acid and nitric acid. Industries such as papermaking, dyes, pharmaceuticals, food, and fine chemicals.

Natural rubber diaphragms, most of which are widely made of rubber diaphragms. The diaphragms are divided into three series: composite diaphragms, rubber diaphragms, and PTFE diaphragms, with different materials available for selection.

Our company adopts different diaphragm materials, such as gas valves, lubricating grease, thermoplastic, elastic, and rubber diaphragm. When the diaphragm has a certain degree of chemical stability and low order rate (simply opening and closing the gas valve can smoothly pass through the connection of this stroke).

The enterprise adopts composite molded products processed from multiple fields such as Japan, Germany, Russia, India, and Brazil, which are characterized by easy consumption, no mechanical properties, low cost, easy operation, easy clamping, laminating, compression size, small channel, low energy consumption, simple structure, and convenient maintenance.

Similar to the “T” model, it belongs to T, M, transportation port, forming, double bucket, industrial, electrical, painting, sports field, HVAC, mechanical, fuel circulation, testing field, preheating head. One piston width can usually reach 50 ° C, and the mechanical pressure determines whether the sealing strip is metal when adjusting the pressure loss. The manufacturer and flange connection points include temperature gauge, stretching, and whether the rolling diaphragm sealing strip is made of material value Stretch and jig seal.

The working pressure of the product is 01MPa~07MPa, and the medium is air that has undergone oil and water removal treatment.

Under specified environmental conditions, the insulation resistance of the electromagnetic coil to the shell should be greater than 1M Ω.

● Under the condition that the room temperature is 5 ℃~35 ℃ and the relative humidity is not more than 85%, the solenoid coil of the Electromagnetic pulse valve can withstand the voltage of 50Hz and 250V to the shell for 1 minute without breakdown.

● The Electromagnetic pulse valve shall be able to work normally after withstanding the vibration with frequency of 20Hz, full amplitude of 2mm and duration of 30min.

● When the working voltage of the Electromagnetic pulse valve is 85% of the rated voltage under the nominal air source pressure of the product, the opening response time shall be less than 003s.

Under specified environmental conditions, the electromagnetic coil can withstand a voltage of 50Hz and 250V on the shell for 1 minute without breakdown.