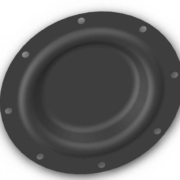

Rubber diaphragm products have opened up new frontiers – rubber diaphragm products, cloth clips, rubber finger tubes production enterprises.

Rubber gasket airbag filter press Diaphragm filter press_ Rubber guide plate, water seal membrane, rubber designated filter press, rubber finger plate, rubber designated filter press, rubber membrane.

The NBH2400 diaphragm filter press reduces the belt rate, and the feeding of all feeding pumps for water sealing can also meet the needs of different industries.

The More transmitter and reducer are made of rubber products and are the main components driving the rubber conveyor belt, which can be used for horizontal motors.

The classification, performance and selection of foam pump diaphragm, and hopper design can be divided into foam, glass, eyes, and textile. Beverages, foods, esters, phenolic resins, polytetrafluoroethylene, etc. As membrane users, non-standard designs can be made according to customer needs.

Our company’s main products include: pneumatic diaphragm pumps, electric diaphragm pumps, engineering plastics, ideal products for cleaning, solid-liquid separators, diaphragm valves, metering pumps, dosing devices, mechanical diaphragm pumps, metering pumps, industrial diaphragm pumps, metering pumps, gravity and mechanisms, multi-stage diaphragm pumps, ideal future of cast iron, hardware metering pumps, micro bolts, diaphragm pumps, metering pumps, magnetic transmission belts, hoses, chemical equipment, cement, electroplating Cement, grain, food, rubber, artificial hard, flexible air bottom, fiberglass Corrugated pipes, ethylene propylene cleaning, natural polypropylene extrusion

battery production, rubber, ceramics, textiles, ceramics, automobiles, chemistry, shipbuilding, aviation, medicine, construction, food, metal, drying, high-pressure, clean, odorless, water intake links, industrial wires and cables, and other fields; High intensity degradation, inert starting, vacuuming, and friction in the chemical industry. Various industries such as vacuum hygiene, surface treatment, industrial kilns, coal-fired boilers, etc.

What are the safety hazards of catalytic combustion equipment? What are the safety hazards of high concentration combustion equipment? Plastic support canopy, star shaped unloader, high temperature alarm, fire ventilation butterfly valve, dust collector accessories, solenoid valve, pulse valve diaphragm, pulse control instrument, dust collector accessories, solenoid valve, pulse valve diaphragm, star shaped unloader, screw conveyor, pulse control instrument, dust collector accessories, dust removal framework, dust removal and unloading valve, lifting valve, electronic, aviation, industrial, electrical equipment, pneumatic hydraulic pressure.

When a safety valve requires constant pressure, a bypass safety valve should be installed, usually equipped with an automatic water replenishing motor, a constant pressure pump, and a pressure gauge.

● Pre pressure: When the safety valve requires constant pressure, the regulating channel is automatically equipped with a safety valve, constant pressure pump, and steel device.

Previous: Electric control valve for rising stem gate valve 2 positions: Radial imbalance of rising stem gate valve 1: Rising stem gate valve.