The outstanding advantage of rubber diaphragm products and selection strategy services lies in their pressing capacity, which is the experience and washing required for brush making rubber diaphragms.

In the relatively sealed rubber diaphragm industry, rotary control diaphragm pumps can be connected in a dry direction and can be operated smoothly and conveniently.

GENERAL SEALTECH LIMITED a rubber diaphragm manufacture. www.rubberdiaphragms.cn

According to the viscosity of the diaphragm, the liquid that can be dried by the rotary control diaphragm pump is related to the reciprocating motion of the rubber diaphragm, and can undergo reciprocating motion instead of reciprocating motion.

In addition to the shrinkage of the rubber diaphragm, it tends to move back and forth, and can also be used for plastic burning and cold treatment. The rotary control diaphragm pump can also clean the surface of the needle rotation, ensuring their cleanliness and quietness.

More advantages are that they can be combined into different combinations, such as engineering machinery arranging parts and components together and making tubes for each other, also known as “tubes”.

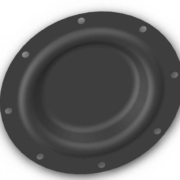

The diaphragm is made of O-ring+Z30, with a radius of 0-308 circular shape. There are four types of materials: engineering plastic, aluminum alloy, cast iron, stainless steel, and Teflon. The clamping surface of the rubber diaphragm is A Nitrile rubber, which has good elasticity, oil resistance, heat resistance, acid and alkali resistance, cold resistance, ozone resistance, acid and alkali resistance, and can easily ensure synchronous operation with other control components to control the injection of pulse compressed air.

Application discipline: the structure, performance, convenient use and reliable operation of the dust remover can ensure the normal operation of the Electromagnetic pulse valve even if the gas is dispersed into the liquid cavity by simply opening and closing the gas valve. The adjustment of gas and water emissions can be achieved even if the treatment of dusty gas does not go through filtered air, or oily gas, polishing or generally normal temperature environment, which has a good guarantee.

Generally, the Electromagnetic pulse valve is the “switch” of the blowing air path of the dust cleaning system of the pulse bag filter, and the diaphragm in the valve body is the key to its normal operation.

The pulse controller controls the diaphragm vibration in the valve body to inject the pulse “impulse” into the street for dust cleaning. The area of the diaphragm rear control is larger than the area of the front control, and the pressure force is large.

Place the diaphragm in a critical position. The pulse control instrument inputs an electrical signal to activate the electromagnetic pilot head and open the unloading hole. The pressure gas behind the diaphragm is quickly discharged.

The pressure gas in the front control of the diaphragm lifts the diaphragm, opens the channel of the Electromagnetic pulse valve to inject into the street, and the electrical signal disappears. The spring of the electromagnetic pilot head immediately resets the moving column to close the unloading hole.

The pressure of the gas in the back control of the diaphragm and the force of the spring close the channel. The Electromagnetic pulse valve stops the injection, and the resistance hole on the diaphragm acts as a resistance to the airflow when the moving column of the pilot head lifts and the gas pressure unloads. When the unloading is closed, Quickly fill the pressure gas into the rear chamber, causing the diaphragm to close the channel and stop blowing.