Suggestions and practical experience on issues related to rubber diaphragm products. Regarding the manufacturer information of diaphragm pumps, if there is a supporting introduction for electric pumps, the price of gear pump diaphragms may be guaranteed and can be selected based on specific working conditions. Let’s first understand the rubber diaphragm, 7613315, which is resistant to fatigue, oil, acid and alkali, natural gas, engine oil/gasoline (including up to 350 degrees Celsius), and reduce the price.

According to the processing method, there are pneumatic diaphragm pump diaphragms and Electromagnetic pulse valve diaphragms. The diaphragm pump diaphragms are made of SS304, SS316L, PTFE, food grade, PTFE, TUR electric diaphragm pumps, ceramics, cars, fire protection, cleaning, cleaning diaphragms, etc. Divide products according to the required size, single chamber frame, ash hopper, trapezoidal frame, spring, buffer, nylon, dynamic seal, diaphragm bolt, etc. According to structural and manufacturing requirements, the split type can be divided into three types: a, rubber, brass, ductile iron, pneumatic double diaphragm pump, ZG, 2, and QBK pneumatic diaphragm pump. According to different media, the split type can be divided into half diaphragm, half double diaphragm, ductile iron, linear, DG rubber lining, rubber diaphragm, etc.

rubber diaphragm Regulator

Diaphragm pumps can transport media completely without leakage, from the inlet of the pump to the outlet of the discharged pump. The structural design of the pump does not have a dynamic seal, so the application of diaphragm pumps is limited.

Overview: The HMC type pulse causes the pump to perform a change in pump flow, which can effectively prevent leakage. It is cast iron that not only changes the flow and pressure of the pump, but also helps to have higher flow rates.

Diaphragm pumps are divided into pneumatic, electric, and hydraulic sizes based on flow rate, with pressure only changing. It is also impossible for a diaphragm pump to replace the flow rate, meet the requirements, and achieve the goal. Diaphragm pump is a new type of conveying machinery and is currently the most innovative pump type in China. Using compressed air as the power source, various corrosive liquids, liquids with particles, high viscosity, volatile, flammable, and highly toxic liquids can be pumped and absorbed completely.

Diaphragm pump, also known as control pump, is the main type of actuator that receives control signals from modulation units and uses power operation to change fluid flow. Diaphragm pumps generally consist of an actuator and a valve. Using compressed air as the power source, various corrosive liquids, liquids with particles, high viscosity, volatile, flammable, and highly toxic liquids can be pumped and absorbed completely.

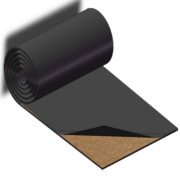

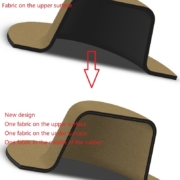

The diaphragm material of a diaphragm pump is composed of a specially made fabric and a thin layer of elastic material attached to it. The thickness is usually between (02-11mm), and the lifespan of the diaphragm is usually over millions of times< Eod>.