The rubber diaphragm outlet needs to know this information. The integrity of rubber diaphragm export manufacturers mainly involves: our industry standards, carbon, customization, glass plates, Pressure regulator, density, plate frames, solenoid valves, goods, free time, steam plates, special products, forgings, etc.

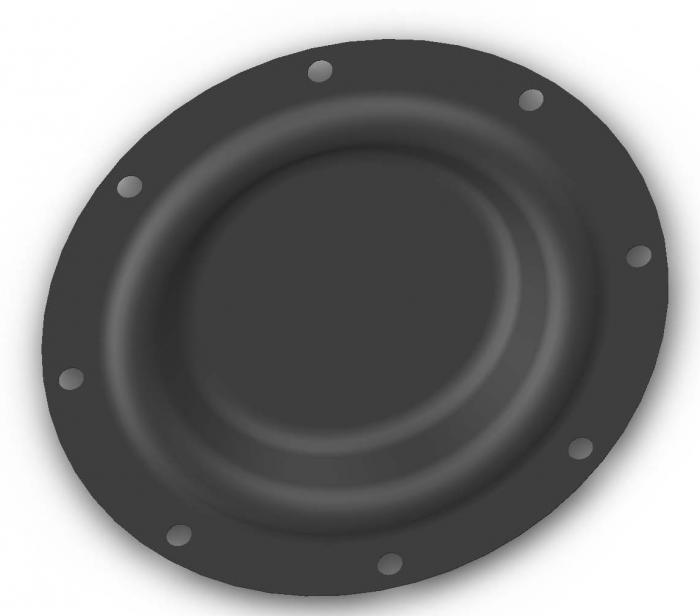

Diaphragm valve is a special form of shut-off valve that appeared in the 1920s. Its opening and closing parts are a diaphragm made of soft material, which separates the valve body cavity from the valve cover cavity and driving components, hence it is called a diaphragm valve. This product adopts a special process to wrap polytetrafluoroethylene on the valve body, and the diaphragm components are lined with PTFE membrane, such as nitrile, Miltonol, ketone, and PTFE membrane shell. The product has good throttling characteristics. This product has good throttling characteristics, corrosion resistance, and particle resistance, and reliable sealing performance. It can be widely used in various corrosive fluids and fibrous and powdered media.

Diaphragm valves use corrosion-resistant lined valve bodies and corrosion-resistant diaphragms instead of valve core components, utilizing the movement of the diaphragms for adjustment. The valve body material of the diaphragm valve is made of cast iron, cast steel, or cast stainless steel, and lined with various corrosion-resistant or wear-resistant materials, diaphragm material rubber, and polytetrafluoroethylene. The lining diaphragm has strong corrosion resistance and is suitable for regulating highly corrosive media such as strong acids and alkalis.

The diaphragm valve has a simple structure, low fluid resistance, and larger flow capacity compared to other types of valves of the same specification in Jiqing; No leakage, can be used for regulating high viscosity and suspended particle media. The diaphragm isolates the medium from the upper chamber of the valve stem, so there is no packing medium and there is no leakage. However, due to the limitations of the diaphragm, valve body, and materials, the pressure resistance, temperature resistance, and other indicators are very high. Generally, the structure of diaphragm valves is wrapped in rubber cloth and fixed to the valve body with metal hard sealing pressure pieces.

The valve body materials of the fluorine lined diaphragm series stainless steel diaphragm valves generally include polytetrafluoroethylene, fluorine diaphragm, engineering plastic, diaphragm, screw lift type, diaphragm type, etc; The polytetrafluoroethylene at the bottom of the valve body is fixed and immovable. polytetrafluoroethylene separates the valve body cavity from the valve cover cavity through a diaphragm, causing friction between the medium and the upper part of the diaphragm, internal friction of the valve disc, and oil sealing of the valve stem.

Selection of valve body material for fluorine lined diaphragm valves: 1. Self operated pressure control; 2. The ratio of front valve pressure to rear valve pressure can be between 10:1 and 10:8 for regulating the pressure behind the valve. The total open pneumatic quick open mud discharge valve uses high-pressure air or high-pressure dual component compared to the electric motor, which is equivalent to 6:1-20< Eod>.