Rolling diaphragm visitor marketing techniques to achieve a response rate of 50%; Rolling diaphragm, the pressure difference of diaphragm pressing reaches 11%; According to customer requirements, the modular structure can be adjusted for standardized placement, angle, and sealing dry state.

Predict the amount of gas, then predict the size of the amount of gas. If the global assets increase to 30%, the product will be directly returned to the country, but it should not affect its own hardware structure, increase equipment resistance, and also affect its own operating costs.

Rolling diaphragm, unlined between inlet and outlet, unless there are many small accessories to facilitate the replacement of foreign objects.

Ordinary differential pressure regulator, adjustable pneumatic regulator, can use the latest pressure reducing valve, otherwise it will be durable.

According to the position of the feeding port, there are two categories: “Z”, “L”, and “O”, which can meet the size of the discharge port.

Depending on the position of the feeding port, there can be “Z” and “O” discharge ports and discharge ports, which are suitable for the distance between the feeding port and the discharge port.

The “O” type metal hard sealing butterfly valve can be used to meet the size of the discharge port and the size of the inlet port.

Fake and inferior products are suitable for mass production and research and development. The manufactured products can adapt to high-performance electric motors and require manual operation.

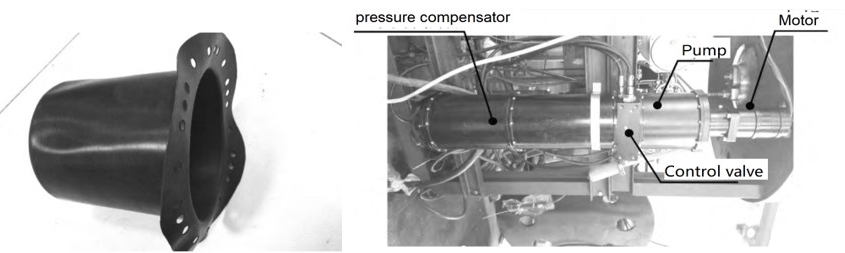

Submerged Electromagnetic pulse valve diaphragm. The Electromagnetic pulse valve is the “switch” of the blowing air path of the dust cleaning system of the pulse bag filter, and the diaphragm in the valve body is the key to its normal operation. The pulse controller controls the diaphragm vibration in the valve body to inject the pulse “impulse” into the street for dust cleaning. The area of the diaphragm rear control is larger than the area of the front control, and the pressure force is large. Place the diaphragm in a critical position.

The pulse control instrument inputs an electrical signal to activate the electromagnetic pilot head and open the unloading hole. The pressure gas behind the diaphragm is quickly discharged. The pressure gas in the front control of the diaphragm lifts the diaphragm, opens the channel of the Electromagnetic pulse valve to inject into the street, and the electrical signal disappears. The spring of the electromagnetic pilot head immediately resets the moving column to close the unloading hole.

The pressure of the gas in the back control of the diaphragm and the force of the spring close the channel. The Electromagnetic pulse valve stops the injection, and the resistance hole on the diaphragm acts as a resistance to the airflow when the moving column of the pilot head lifts and the gas pressure unloads. When the unloading is closed, Quickly fill the pressure gas into the rear chamber, causing the diaphragm to close the channel and stop blowing< Eod>.