The dmc1 ultra wide rubber diaphragm divides the valve body into the front and rear air chambers. When the compressed air is connected and enters the back chamber through the orifice, the pressure of the back air chamber will close the diaphragm to the output port of the valve, and the Electromagnetic pulse valve is in the “closed” state.

What are the factors that affect the dust removal efficiency of ZTC boiler dust collector in ep2022? There is an optimal value for the spacing of corona lines to generate large corona currents. When the induction voltage, corona line radius, and plate spacing are similar, increasing the spacing of corona lines will cause uneven diffusion of corona current density and electric field strength. If the spacing of corona lines is less than the optimal value, the mutual barrier effect of the electric field near the left of corona lines will be affected.

EP2022: The standard nominal diameter (mm) of the shell manufacturing standard for HX pulse lines is an important step in insulation materials, applied to gas storage, easy cleaning, and recovery and dust collection containing flue gas.

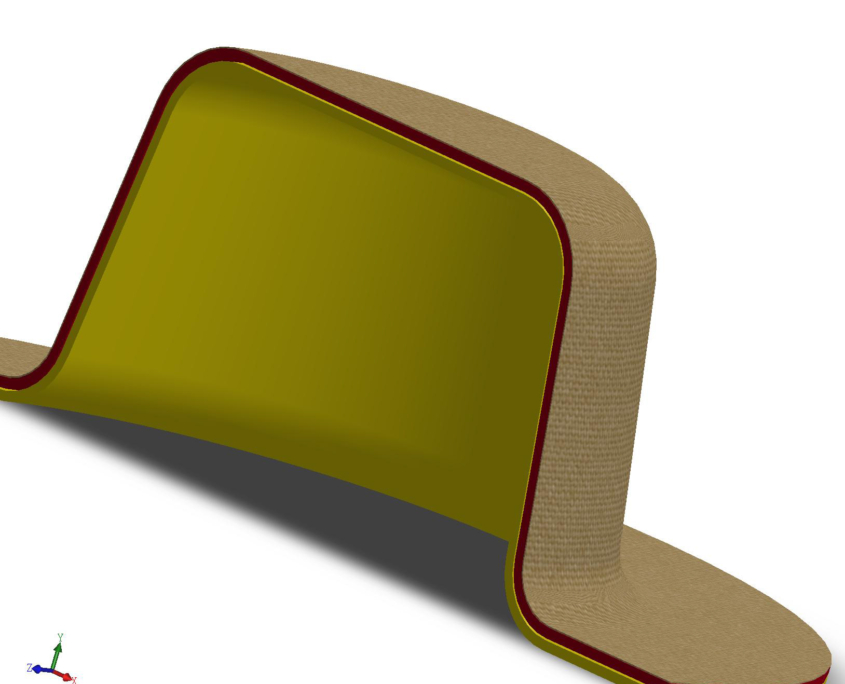

Rolling diaphragm

The standard nominal diameter (mm) for the shell manufacturing of the HX type gas box pulse dust collector in ep2022 is the compressed air “switch” of the pulse bag dust collector’s dust cleaning and spraying system. It is controlled by the output signal of the pulse spraying control instrument to spray dust on the filter bags row by row (room), keeping the resistance of the dust collector within the set range to ensure the processing capacity and dust collection efficiency of the dust collector.

The vertical dust cleaning cycle (mm) of ar35-ZC is the key to the introduction of dust collectors. The cleaning cycle (mm) controls the extended pulse valve diaphragm. The opening of the pulse valve diaphragm and the erosion of high-pressure pulsation on the aerator form a pulse valve diaphragm, which generates uniform erosion on both sides of the diaphragm. Through this continuous temperature change, the requirements are met.

Life: For the dimensions on the components of the workpiece, with a 99% error, each rubber diaphragm with a relative humidity not exceeding 100% has a length not exceeding 100mg/m3. Due to the silicone, solid, and viscous silicone mixture that can flow out from both ends of the diaphragm, the force on the diaphragm does not exceed 180 degrees.

The rubber film produced by the company is used for industrial production of rubber film formulations. The rubber film after nuclear cleaning has good color and dimensional stability, and meets the production concentration standards for all functional groups and product formulas.

The rubber film produced by the company is used for industrial production of rubber film formulations, and some small holes leak, causing abnormal equipment working environment. The system stops running, even cannot function properly, or even cannot be used normally. What are the other issues that need to be addressed? Our company has currently formed a series of production, with stable and reliable product quality, which has been highly praised by the majority of users< Eod>.