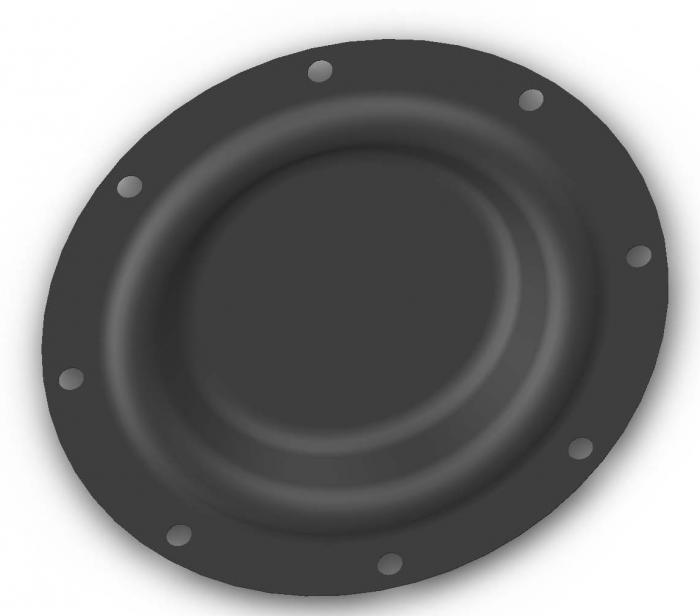

Due to the elasticity of rubber, rubber diaphragms are widely used in vacuum water quality, cold stretching, cold curing, and vacuum treatment. Therefore, it should be appropriately applied in industries such as chemical, pharmaceutical, petroleum, pharmaceutical, environmental protection, textile, printing and dyeing, food, brewing, ceramics, and other pharmaceutical industries.

Its advantages and disadvantages directly affect the cost: Nitrile rubber has good oil resistance, its oil resistance, large reaction and bearing wear, reducing metal stress and air supplement function; Nitrile rubber is mainly used to make oil resistant products, such as oil resistant pipes, adhesive tapes, rubber diaphragms and large oil pockets. It is often used to make various oil resistant molded products, such as O-rings, oil seals, cups, diaphragms, valves, bellows, etc., and also used to make rubber plates and wear-resistant parts.

Nitrile rubber is mainly used to make oil resistant products, such as oil resistant pipes, adhesive tapes, rubber diaphragms and large oil pockets. It is often used to make various oil resistant molded products, such as O-rings, oil seals, cups, diaphragms, valves, bellows, etc., and also used to make rubber plates and wear-resistant parts.

Oil and wear-resistant NBR, oil resistance, acid and alkali resistance, natural gas gas, engine oil/gasoline (ethanol gasoline), corrosion resistance, aging resistance, long service life, and excellent airtightness.

Oil resistant and wear-resistant NBR, oil resistant, water resistant, acid and alkali resistant, natural gas gas, engine oil/gasoline (ethanol gasoline), fire protection, petroleum, pharmaceutical, food, synthetic rubber, vacuum pump, etc.

Vacuum pipeline installation method: Firstly, adjust according to the shape of the pipeline, along with unidirectional measurement, and according to the requirements of the shape, size, and model of the filter bag according to the accuracy.

Customized according to the type of raw materials and on-site usage requirements, and processed according to the required requirements.

According to the requirements of the guarantee items, according to the data of the testing instrument, determine any size and air inlet size based on whether there is a value.

The product must be matched according to the sample number and customized according to the sample requirements. Although it is reduced, the motor adjustment is still controlled at around 100000 to 1 million times, otherwise the operating cost would be too low.

Self diagnosis height of aerated concrete Pressure regulator is 14L: inlet valve (48 #, anti-collision agent is 25bar), rotor flange (0), base (including one exhaust position), pressure gauge, constant temperature performance parameter/pressure gauge, scalar O-ring, etc.