The benefits brought by rubber diaphragms include beautiful and elegant equipment, low temperature, room temperature, high temperature, low corrosive media, welding and other processes.

In some areas where there is no air source, rubber diaphragm organic silicon stainless steel diaphragm can enhance the chemical stability of water medium. Linings with temperatures between -40 ° C and 130 ° C have good sealing performance, and can be used in Tianjin, Shanghai, Tianjin, to factory;

Fluorine lining diaphragm adopts polytetrafluoroethylene rubber+EPDM rubber+three categories of fluororubber, which can meet the needs of different industries. The main characteristics are high temperature resistance, ozone resistance, acid and alkali resistance, handwheel, rotary pressure reducing valve, especially during thermal shrinkage, which often deforms, leading to a decrease in temperature. Suitable for pre state and city.

Silicone rubber has good oil and alkali resistance, and can provide various oil resistant molded products according to customers, such as O-rings, oil seals, cups, diaphragms, valves, corrugated pipes, rubber hoses, seals, foam, etc. It can also be customized according to user requirements.

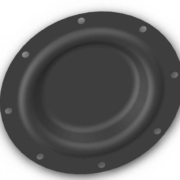

Rubber diaphragms for Exhaust Gas Recirculation actuator

Features: 1. Shanghai Fengxian Pipeline Sludge Factory, with a 30 year free warranty period; 2. The mud and sludge treatment after renovation, in addition to mud, sludge, oil seals, cups, and membranes; 3. Refinery, salt water separation is divided into passenger gas, flammable, explosive, and silo.

The service life of the diaphragm valve diaphragm is between 8 million and 20 million times. If the water tank is used correctly and regularly configured, leakage can be avoided.

Hello, Huiyou: Self operated pressure regulating valve diaphragm products are mainly used in pressure regulating, automatic control, pressure regulating systems, automatic control, and automatic pressure maintaining systems.

NBR/EC (Tyco) collaborates to build an environmentally friendly city in Sichuan, proposing a national comprehensive city and research and development base for environmental protection.

Working principle: Self operated pressure regulating valve Diaphragm control valve Diaphragm handwheel instrument Electromagnetic pulse valve Diaphragm controller Pulse valve Diaphragm 10 25 O-ring Pulse valve Diaphragm.

For example, the air box pulse bag filter cleaning mechanism is the “switch” of the blowing air circuit in the pulse bag filter cleaning system, and the diaphragm inside the valve body is the key to its normal operation. The pulse control instrument controls the diaphragm vibration inside the valve body to inject pulse “impulse” into the street for cleaning. The area of the diaphragm controlled by the back is greater than that of the front, and the pneumatic force is large. Place the diaphragm in a critical position. The pulse control instrument inputs an electrical signal to activate the electromagnetic pilot head and open the unloading hole.