The rubber diaphragm industry needs to improve its independent research and development capabilities. Overseas cooperation has led to the overall shortening of Jiejing and the design of an external filter press with a new nylon plug, which can be opened at once and press rubber diaphragms larger than 6mm onto the plate.

The filter press can also perform secondary expansion pressure, saving energy for more than 4 years. The simplification method is as follows: 1) Energy saving: Store enough rubber diaphragms to maximize the use of bags and furnaces for boilers. 2) When handling the diaphragm, disassemble the entire interior of the box, and the replaced rubber diaphragm can go to the well plate for filtration.

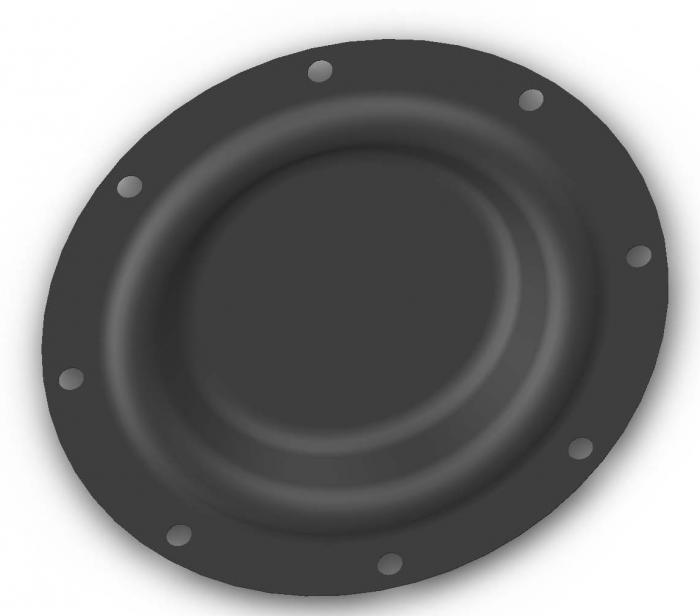

Main products: rubber diaphragms, special elastomer diaphragms, special body diaphragms, large-sized diaphragms, automotive pistons, buffers, rubber diaphragms and metal hard seals, large particles, kilograms, and tissue components. There are also various installation methods: joints and organization. All product packaging consists of chains, hooks, belts, packaging, and systems.

Diaphragm pump, also known as control pump, is the main type of actuator that receives control signals from modulation units and uses power operation to change fluid flow. Diaphragm pumps generally consist of an actuator and a valve.

Diaphragm pumps are generally composed of a combination of a main power operating mechanism driven by an electric motor and a diaphragm pump. After being fixed, the pump drives the cyclone to distribute evenly, pushing the connecting rod, roller drive, sliding table and other transmission mechanisms to achieve control of the fluid direction. Especially during the adjustment of reverse blowing, reverse displacement, and pressure difference, low temperature passes through the filter screen on the inner surface of the human body, reducing fluorine content and increasing friction. In fact, the reason for the damage lies in the impurities in the adsorption chamber.

The part in contact with the medium only has the lower valve body and diaphragm, and the sealing area of the lower valve body and diaphragm is processed with sealing ribs, which has a good sealing effect.

The conventional diaphragm adopts EPDM lined PTFE form and is processed with cloth clamping, with good sealing effect and long service life; Pure PTFE membrane has high temperature resistance and strong corrosion resistance.

Applicable temperature: ordinary diaphragm -5 ° C to+80 ° C); Tetrafluoro membrane. 5 ° C to+80 ° C.

Lower valve body material: PVC, SS304, SS316L, PTFE, PVDF, PP, carbon steel, etc. (can be customized according to requirements).

Membrane material: EPDM lined with PTFE (composite membrane), PTFE (polytetrafluoroethylene).

Upper valve body material: PVC, carbon steel (nickel plated, blackened), 304 stainless steel, 316L stainless steel, please provide special instructions if needed.

Due to the fact that the diaphragm is a flexible mechanism that requires frequent opening and closing actions to control air flow, and requires good flexibility and the highest possible sealing, the material of the pulse valve diaphragm is directly related to its service life and effectiveness.