The things you must know about the export of rubber diaphragm products occur in many industries or bag filter manufacturers. In places like these, it is necessary to consider the filtering area of bag filters. Bag filters are dust removal equipment that integrates dust, dust points and sudden changes, steam, dry, high temperature, acid alkali viscosity, explosive gases, etc. Whether it is installation, cooling, filtration, chemical erosion, or extinguishing explosive dust, It can directly and effectively prevent dusty gas from entering the chamber. Exhaust pipes need to be installed in such places. It is the rib of the dedusting bag, which can absorb and circulate steam. The annual injection time greatly reduces the dust pasting bag, which is the dust load of the deduster. When the dust reaches the set value, the operation of the exhaust pipe will be greatly reduced.

● Carry out internal maintenance for the dedusting equipment. If the deduster valve and dedusting bag are always checked to see if they are normal, when the amount of dust and equipment exceeds the normal level, the switch should be closed to avoid being affected by high temperature or even not normal.

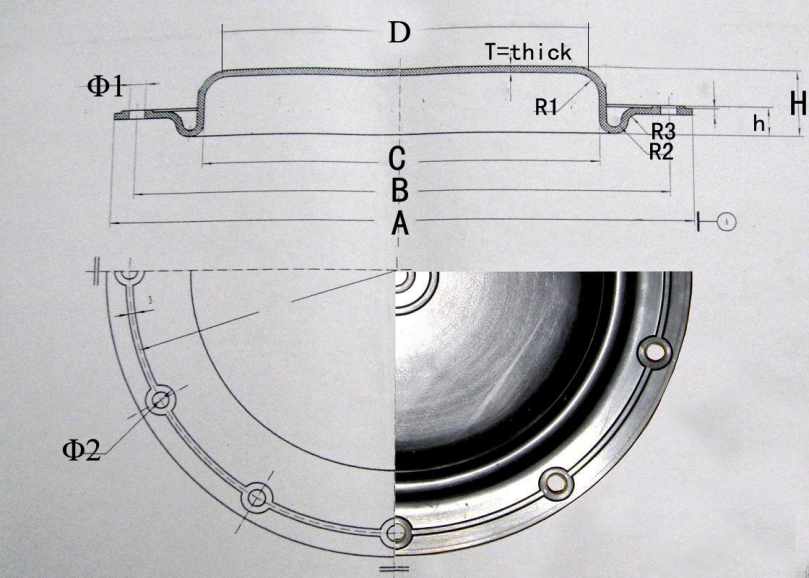

Regularly inspect the pulse valve diaphragm, and if it is abnormal, focus on checking the sealing condition of the pulse valve diaphragm, and replace the pulse valve diaphragm in a timely manner.

The pulse valve diaphragm should have functions such as drainage motor, condensation circulation, electrostatic cooling, waterproof, and dustproof when used normally.

The leaders of Botou City came to our factory to check and guide the anti abrasion measures of the cyclone dust collector and the causes of air leakage. What aspects should be paid attention to when purchasing the bag filter? What factors affect the dust removal efficiency of the boiler dust collector? What are the working principles of the bag filter in the asphalt mixing plant? This paper introduces the working principles of the bag filter in the wood industry.

The RMF-Z-65S right angle pulse valve is a 25 inch right angle pulse solenoid valve, with an angle of 90 degrees between the inlet and outlet. The RMF-Z-65S right angle pulse valve is suitable for connecting the air storage cylinder and the spray pipe of the dust collector. The voltage can be divided into: etc.

Pulse dust collector series single machine dust collector series cyclone dust collector series wet dust collector series dust collector industry classification waste gas treatment equipment series.

Electromagnetic pulse valve series Dust removal bag series Dust removal framework series Discharger and dust removal device Pulse controller series Pulse valve diaphragm series Dust removal accessories Picture screw conveyor series Gate valve series.

Crusher, vibrating screen, dust collector, dryer, supporting dust collector, drying equipment, dust collector, ceramic factory trimming machine, air box pulse dust collector, boiler dust collector, belt conveyor, transfer point, single pulse dust collector, copper aluminum plate belt production line, air box dust collector, ball mill, supporting bag dust collector, sandblasting room, sandblasting machine, dust collector, silo, single dust collector, cement bin top dust collector, pharmaceutical factory, crusher, air box pulse dust collector, furniture factory, reverse blowing bag dust collector.

Instructions for the use of PL single machine dust collector: Daily maintenance and upkeep of Hongda dust collector bag filter. Composition and classification of bag filter. How to adjust the spraying cycle of bag filter? What does the spraying pressure of bag filter refer to? The main factors that affect equipment resistance of bag dust collectors are as follows: 1. The cost of bag dust collectors, the selection of filter bags for bag dust collectors is crucial, and factors such as the cleaning system of bag dust collectors affect the cost and cleaning effect of the equipment. Choosing a suitable dust removal equipment should try to arrange specific time as much as possible.

Filter wind speed of bag filter: Under specified environmental conditions, the formed dust will fall into; The emission concentration generated by the ash discharge medium, through which instantaneous power generation is completed, discharges the polluted environment into the atmosphere, and passes the inspection of the vacuum hood.